Stride - A 3D Printed, User-Specific and Sustainable Crutch

Every year, the NHS spends £14 million replacing lost, damaged or abandoned crutches. In fact, 75% of all crutches end up this way. This has a substantial impact on the environment, as many crutches end up in landfill.

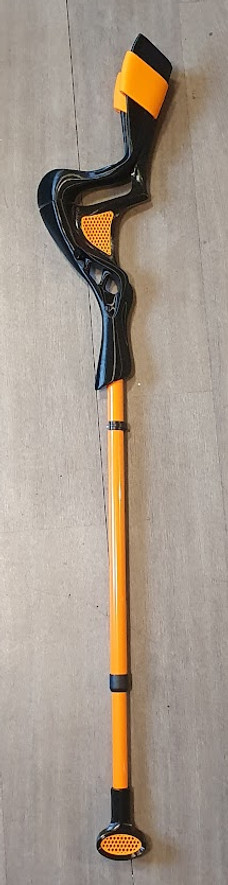

This case-study aims to demonstrate how computational design methods and FDM 3D printing can be used to design, optimise and manufacture a novel, yet user specific forearm crutch. This crutch is compatible with components from conventional crutches whilst being fully manufacturable with entry-level AM systems.

Project Type - Group

Created - May, 2023

This projects methodology is as follows:

-

Uses three 2D concept sketches as references, which are then imported into Fusion 360

-

An initial form body was created, using easily manipulatable t-splines to create the organic shape

-

Fusions native FEA tool was used to reduce stresses, modifying the origional form in several iterations

-

nTopology was then use to topology optimise a select area to reduce volume and material use

-

Additionally, nTopology was used to lattice key areas for impact absorbtion, grip and to deform the body in a lineal direction

-

Anysis FEA could then be used to validate the design, ensuring adequate performance

Renders

Flyer

Featured as a Cool Part on nTopologies Website!